FAW Jiefang 16m Articulated Aerial Work Platform Truck

Engineered for precision in confined spaces, the FAW Jiefang 16m Articulated Aerial Work Platform is your reliable partner for efficient and safe aerial operations. Built on the robust FAW 4x2 single-axle chassis with a 3900mm wheelbase, this vehicle combines proven mobility with a highly versatile 3-section articulated arm. The boom's unique design allows it to fold from 0 to 70 degrees relative to the horizontal plane, enabling it to effortlessly reach over and around obstacles, making it the ideal solution for complex urban maintenance tasks like street light repair and power line maintenance.

FAW Jiefang 16m Articulated Aerial Work Platform Truck

Key Features & Superior Advantages

●Unmatched Maneuverability with Articulated Boom

The core of this platform is its 16-meter high-reaching, three-section articulated arm. Unlike straight booms, this jointed design provides exceptional flexibility to access difficult-to-reach areas, from behind obstacles to deep into narrow spaces, ensuring no job is out of reach

●Engineered for Electrical Safety

Safety is paramount, especially around power sources. This platform is equipped with a fully insulated bucket rated to withstand 600 volts, providing a critical layer of protection for operators during electrical repairs and high-voltage line maintenance.

●Robust & Reliable Power System

Powering this reliable machine is a Yuchai 4-cylinder, 130 HP engine, paired with a dependable domestic Wanliyang 6-speed manual transmission. This combination ensures ample power and fuel efficiency for both transit and on-site operation. The 2-ton front and 9.8-ton rear axles provide a stable foundation for all lifting tasks.

●Enhanced Stability and Operational Safety

For maximum safety during operation, the vehicle features H-type front and rear outriggers. All four stabilizers are equipped with hydraulic locking devices, securing the platform firmly on the ground. The hydraulic system itself is designed with redundancy in mind, incorporating 11 oil cylinders and bidirectional balance valves or hydraulic locks on critical functions to prevent accidental movement.

●Durable Construction for Long-Term Use

The aerial structure is built from high-strength Q345 steel profiles with a 4mm thickness, ensuring long-term durability and resistance to fatigue. The 65L hydraulic tank with a level gauge and a system operating pressure of 16 MPa guarantee consistent and powerful performance.

Ideal Application Scenarios

This versatile aerial platform is perfectly suited for a wide range of industries and tasks, including:

1.Power Industry: Ideal for power emergency repairs and high-voltage line maintenance in urban and rural settings.

2.Municipal Maintenance: The go-to choice for efficient street light maintenance, bridge inspection, and other public infrastructure upkeep.

3.Landscaping & Forestry: Provides a stable platform for tree pruning and maintenance in parks and along city streets.

4.Construction & Installation: Facilitates facade installation, painting, and other building-related tasks.

5.Industrial Plant Maintenance: Essential for installation, cleaning, and repair work inside and outside factories.

Why Choose Our FAW Aerial Work Platform?

· Proven FAW Reliability: Benefits from the rugged and trusted foundation of the FAW commercial vehicle platform.

· Exceptional Versatility: The articulated boom offers superior flexibility compared to straight-boom models, allowing you to tackle a wider variety of jobs.

· Safety as a Priority: With insulated buckets, hydraulic locks, and a stable outrigger system, operator safety is at the core of the design.

· Cost-Effective Operation: The combination of a fuel-efficient engine and durable domestic components ensures a lower total cost of ownership.

· Direct Factory Source & Customization: As a specialized vehicle manufacturer, we provide competitive pricing and can discuss customization options to meet your specific needs.

Product Specification

| Technical Specification | ||

| Chassis Part | ||

| Condition | FAW Tiger VH model , factory brand new 2025 | |

| Wheelbase | 3900mm | |

| Cab | FAW Tiger VH single row and flat roof cabin | |

| Right hand drive With 2-3 people | ||

| Engine | Engine brand | YUCHAI Engine YC4D130-33 |

| Horsepower | 130hp , 96kw | |

| Fuel type | Diesel | |

| Transmission | Manual type, WLY6TS55 , 6 forward speeds and 1 reverse | |

| Clutch | Ф330, hydraulic control with air booster pushing | |

| Front axle loading | 2,000kg | |

| Rear axle loading | 9,800kg | |

| Rear axle speed ratio | 5.286 | |

| Tyre | 8.25R16 14 PR, 6pcs with one spare | |

| Upperstructure Configuration | ||

| Boom | Boom type | Three-section folding arm |

| Material | Q345 profile | |

| Thickness | 4 mm | |

| Boom cross | Quadrilateral | |

| Section undulation angle | 0°-70° (relative to horizontal plane) | |

| Working performance | Maximum operating height | 13m |

| Working range at maximum working height | 3m | |

| Outriggers | Outrigger type | Front and rear H-shaped |

| Leg material | Profile Q345B, 5mm thickness | |

| Leg span | Longitudinal:3240mm; Transverse: 3180mm | |

| Hanging basket | Rated loading | ≤250kg |

| Insulation | Withstand 600volts of voltage | |

| Dimension | 1080*620*1150mm (L*W*H) | |

| Levelling type | External pull rod mechanical levelling | |

| Safety belt | One pair | |

| Hydraulic system | Hydraulic oil tank | 65L, with liquid level gauge |

| Gear pump | Dosing pump, flow rate 25ml/r | |

| Working pressure | With pressure gauge, 16Mpa | |

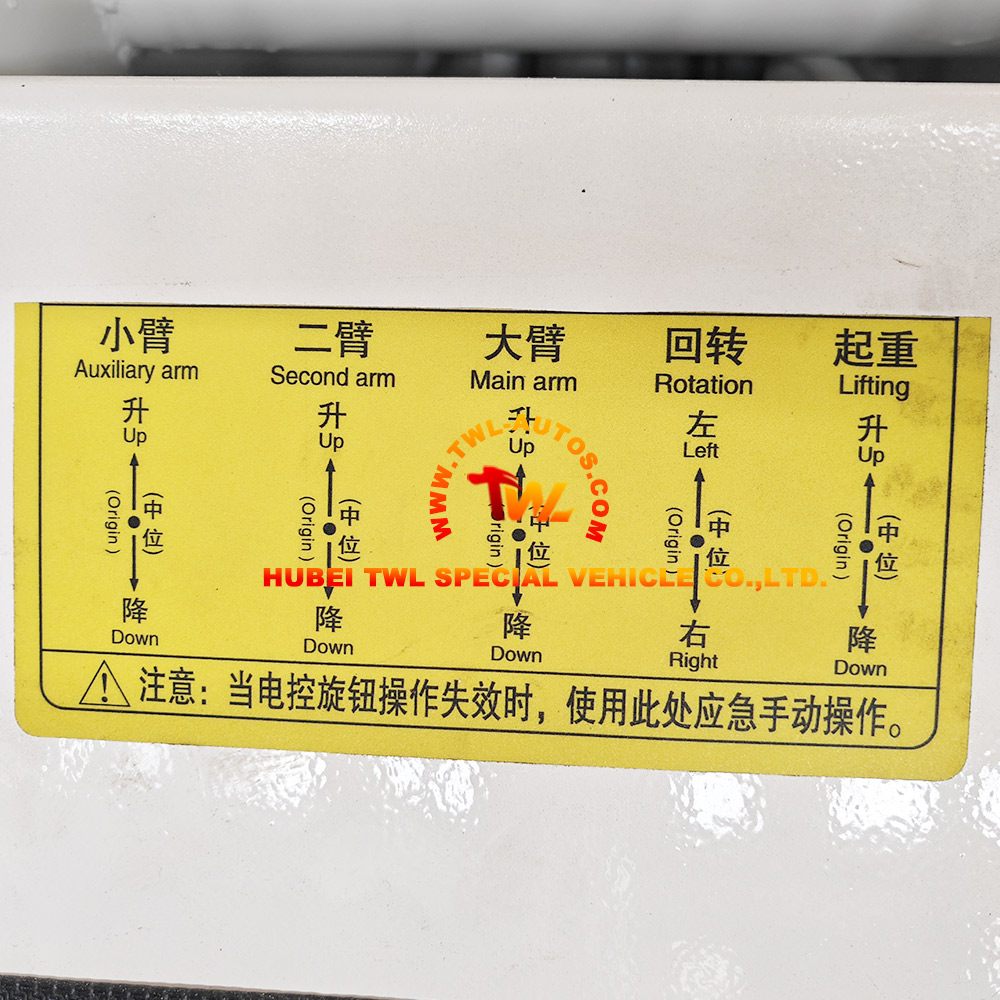

| Operating system | Combination of manual and electric; Electric double-position operation of turntable and hanging basket Dual-position operation of turntable and hanging basket. | |

| Remarks | Color is optional | |

| LOGO painting as per customer request | ||

FAW Jiefang 16m Articulated Aerial Work Platform Truck Gallery

- +86 199 4767 5585

- [email protected]

- Industry Park, Suizhou City,Hubei Province, China

Company Profile

Aout TWL

HUBEI TWL SPECIAL VEHICLE CO., LTD (hereinafter referred to as TWL), one of important member of CLW Group, is located in Suizhou City, Hubei Province, the capital of China’s Special Vehicles. TWL Truck has a first-class management, design, R&D, manufacturing, and sales professional team, as well as “special, new, high and sophisticated” facilities and equipment, complete manufacturing technology, and strict testing methods to ensure the production of high-quality and high-value-added products for the market. At present, we has strategic partnership with a number of well-known Chinese truck brand, including Dongfeng, Sinotruk, FAW, Foton, Shacman, ISUZU, JAC, JMC, Kama, etc. TWL Truck always adheres to the corporate philosophy of “people-oriented, customer-oriented, honesty and win-win”, and adheres to the business tenet of “development by innovation, survival by quality; integrity by service, and market by brand”.

After-Sales Service

Warranty

– The buyers can get a minimum warranty period of 12 months or 25000KM-50000KM, whichever comes first from the arrival date of shipment.

– During this period, we will send replacement parts and components to buyers by DHL, UPS, FEDEX or by air and by sea free of charge, easy-wearing spare parts are excluded.

– After warranty time, buyers can get all of spare parts of their truck at factory cost.

– This warranty does not cover any possible damage due to improper operaton, accident or misuse or damage due to any unauthorized services.

Technical Support

– The buyers can forever enioy technical support anytime and anywhere, overseas technical training before operaton is available at buyers cost or our cost.

Daily Mainteance Suggestion

– We strongly sugest you to buy some amount of basic spare pats along with your truck, the cost will be approximately 500 USD-800 USD/unit, no shipping cost.