30,000 Liters Aircraft Refueling Truck (Jet A-1)

Provided by TWL, the 30,000-liter Aircraft Refueling Truck is a high-capacity, aviation-grade fueling solution designed for safe, efficient, and compliant ground fuel servicing. Built for helicopters and fixed-wing aircraft, this mobile refueler supports Jet A-1 aviation kerosene transport and delivery in demanding airport and airfield environments.

With advanced safety systems, high-flow fueling components, and robust SINOTRUK 8×4 chassis integration, this truck helps operators maximize aircraft availability while meeting strict aviation safety and environmental standards.

30,000 Liters Aircraft Refueling Truck (Jet A-1)

Also known as an aviation jet refueling truck, aircraft fuel servicing truck, or Jet A-1 bowser, this vehicle integrates precision fueling equipment including aviation fuel pumps, flow meters, and refueling nozzles sourced from internationally recognized brands.

The corrosion-resistant tank structure, explosion-proof system design, and intelligent monitoring technology ensure reliable long-term operation under continuous duty cycles. Designed and manufactured by TWL since 2004, the truck supports scalable configurations and future-ready aviation fueling requirements.

Key Advantages

1. Aviation-Grade Safety and Explosion-Proof Design

The truck is engineered with fire-resistant materials, anti-static systems, and explosion-proof components to minimize ignition risks during refueling. Integrated leak detection sensors continuously monitor fuel lines, ensuring early fault detection and full compliance with aviation ground safety regulations.

2. High-Efficiency Fuel Delivery System

Equipped with high-flow aviation fuel pumps, precision flow meters, and professional refueling guns, the system enables fast and accurate fuel transfer. Reduced fueling time directly improves aircraft turnaround efficiency and operational readiness.

3. Durable, Corrosion-Resistant Fuel Tank

The fuel tank is constructed from aluminum alloy or stainless steel materials to resist corrosion from aviation kerosene and harsh environmental conditions. This ensures long service life, reduced maintenance frequency, and consistent fuel quality protection.

4. Environmental Protection and Emission Control

Integrated vapor recovery systems capture up to 99% of fuel vapors during refueling, significantly reducing emissions. Secondary spill containment structures prevent fuel leakage from contaminating soil or water, supporting airport environmental compliance and sustainability goals.

5. Heavy-Duty Mobility for Airport Operations

Built on a reinforced SINOTRUK 8×4 chassis, the truck delivers stable performance across airport aprons, remote airstrips, and challenging terrain. The robust suspension and drivetrain ensure reliable mobility under full-load conditions.

6. Cost-Effective and Low-Maintenance Operation

Automated fueling functions reduce ground crew labor requirements by up to 30%, while modular system design allows fast replacement of key components. This lowers long-term operating and maintenance costs for fleet operators.

7. Future-Ready and Operationally Scalable

The system supports sustainable aviation fuel (SAF) compatibility and automation upgrades. Tank capacities are scalable from 5,000 to 50,000 liters, allowing operators to deploy the same platform for small regional airports or large international hubs.

Applications & Use Scenarios

1. Commercial Airports & Regional Airfields

Ideal for routine refueling of commercial aircraft, helicopters, and regional fleets.

2. Military & Government Aviation

Suitable for air force bases and government aviation units requiring high-safety, high-reliability fueling equipment.

3. FBOs & Ground Handling Companies

Supports fixed-base operators and ground service providers seeking fast turnaround and compliant fueling operations.

4. Remote & Special-Purpose Airstrips

Effective for oil & gas aviation support, emergency response bases, and isolated airfields where mobile fueling is essential.

Product Specification

| Technical Parameter | ||

| Design standard | GB18564.1-2006 Tank vehicles for road transport of dangerous liquid goods Part 1: Technical requirements for metal atmospheric pressure tanks | |

| Item No. | Parameters | |

| Overall Dimension | 12500x2550x3950 mm | |

| Driving Model | Right hand drive | |

| Gross Vehicle Weight | 32000 kg | |

| Curb Weight | 10,800kg | |

| Payload | 21,200kg | |

| Wheel Base | 1800+4600+1350 mm | |

| Axle | Front Axle | VGD95,9500kgx2 |

| Rear Axle | MCX16ZG,16000kgX2 | |

| Suspension | Front Axle | 1500 mm |

| Rear Axle | 2445 mm | |

| Max. Speed | ≥ 90 km/h | |

| Min. Turning Diameter | 19 m | |

| Max. Grade-ability | 30% | |

| Fuel Box | 400L | |

| Engine Model | WP12.400E201 | |

| Engine Type | 4-stroke direct injection,6-cylinder in-line with water cooling,turbo-charging and inner cooling | |

| Engine horsepower | 400HP EUROII | |

| Displacement | 11.596mL (Diesel) | |

| Max. Torque | 1500N.m | |

| Gearbox | HW19710+HW70 PTO,10-speed forward and 2 reverse | |

| Clutch | Φ430 pull-type diaphragm clutch | |

| Cabin | Standard HW76 cabin with one sleeper | |

| 2 Passenger allowed | ||

| with Air Conditioner | ||

| Tire | 12.00R20 (12 pcs with one spare) | |

| Fuel box | 400 L | |

| Aluminum Alloy material | ||

| Exhaust Pipe | At front of Cabin for safety | |

| Loading Medium | Aviation kerosene or aviation gasoline | |

| Volume: | 30,000liters | |

| Tank material: | Tank shell: Aluminum alloy 5182, 5.6mm thickness | |

| End plate: Aluminum alloy 5182, 5.8mm thickness | ||

| Baffles: Aluminum alloy 5182, 5.6mm thickness | ||

| Main equipment | ||

| Pumping system | Self-priming centrifugal oil pump, 2500L/min | |

| Filter separator | 2500L/min | |

| Differential pressure gauge | Equipped | |

| Air eliminator | Equipped | |

| HEPCV underwing refueling nozzles | Single tube 1200L/min, double tube 2200L/min | |

| Fuel filling tube | DN63 | |

| Reel expansion joint | Equipped | |

| In-line pressure control valve | Equipped | |

| DeadMan system | Equipped | |

| Valve | Equipped | |

| Bypass valve (overflow pipe pressure) | Equipped | |

| Pneumatic system | Equipped | |

| Dial gauge | Equipped | |

| Main valve with Venturi tube | Equipped | |

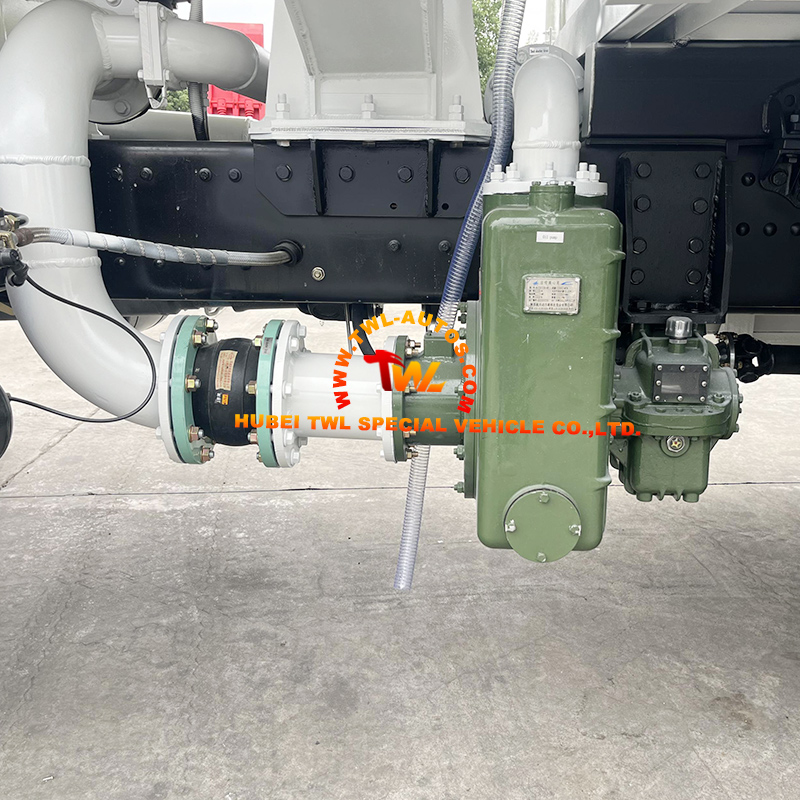

| Swivel joint compensator | Equipped | |

| Flow meter | 2500L/min | |

| Electrostatic reels | Equipped | |

| High level sensor | Equipped | |

| Straight through valve | Equipped | |

| Pipeline fittings | ||

| Manhole | European standard aluminum alloy explosion-proof manhole *2 | |

| Breather valve | 4 sets, Aluminum alloy | |

| Bottom loading | Aircraft fuel coupling | |

| ARVR | Aircraft refueling vapor recovery | |

| Overflow prevention | With anti-overflow system | |

| Safety bottom valve | 8-inch seabed valve*1, high-level valve*1 | |

| Fuel truck gun | DN38 | |

| Hydraulic reel | 20m | |

| Refueling flow | 350L/min | |

| Accessories | ||

| Roof guardrail | Segmented lifting guardrail, tank top anti-slip net | |

| Ladder | Inside and external of the tank | |

| Mudguard | Factory aluminum alloy integral (module stamping) | |

| Side guard | Factory-fitted aluminum profiles | |

| Rear bumper | Factory-fitted aluminum profiles | |

| Fireproofing | 8kg fire extinguisher *2 | |

| Antistatic device | One electrostatic cable, one electrostatic cable tray | |

| Electrical system | ||

| Lamp | 24V system, 7-core socket, LED lamp | |

| Circuitry | Explosion-proof junction box | |

| Wires | Turn signals, brake lights, reverse lights, running lights and fog lights are installed on the left and right of the rear bumper | |

| All wires are sealed with corrugated pipes | ||

| Brake system | Relay valve | |

| ABS system | ||

30,000 Liters Aircraft Refueling Truck (Jet A-1)

- +86 199 4767 5585

- [email protected]

- Industry Park, Suizhou City,Hubei Province, China

Company Profile

Aout TWL

HUBEI TWL SPECIAL VEHICLE CO., LTD (hereinafter referred to as TWL), one of important member of CLW Group, is located in Suizhou City, Hubei Province, the capital of China’s Special Vehicles. TWL Truck has a first-class management, design, R&D, manufacturing, and sales professional team, as well as “special, new, high and sophisticated” facilities and equipment, complete manufacturing technology, and strict testing methods to ensure the production of high-quality and high-value-added products for the market. At present, we has strategic partnership with a number of well-known Chinese truck brand, including Dongfeng, Sinotruk, FAW, Foton, Shacman, ISUZU, JAC, JMC, Kama, etc. TWL Truck always adheres to the corporate philosophy of “people-oriented, customer-oriented, honesty and win-win”, and adheres to the business tenet of “development by innovation, survival by quality; integrity by service, and market by brand”.

After-Sales Service

Warranty

– The buyers can get a minimum warranty period of 12 months or 25000KM-50000KM, whichever comes first from the arrival date of shipment.

– During this period, we will send replacement parts and components to buyers by DHL, UPS, FEDEX or by air and by sea free of charge, easy-wearing spare parts are excluded.

– After warranty time, buyers can get all of spare parts of their truck at factory cost.

– This warranty does not cover any possible damage due to improper operaton, accident or misuse or damage due to any unauthorized services.

Technical Support

– The buyers can forever enioy technical support anytime and anywhere, overseas technical training before operaton is available at buyers cost or our cost.

Daily Mainteance Suggestion

– We strongly sugest you to buy some amount of basic spare pats along with your truck, the cost will be approximately 500 USD-800 USD/unit, no shipping cost.