3-Axle ADR Compliant Side Tipper Semi Trailer

TWL 3-axle ADR side tipper trailers are engineered for durability, stability, and high payload performance. Fully compliant with Australian ADR standards, they are an ideal solution for heavy-duty bulk transport across mining and construction sectors.

3-Axle ADR Compliant Side Tipper Semi Trailer

Our 3-Axle ADR-Compliant Side Tipper Trailer is purpose-built for demanding Australian transport conditions. Designed to fully meet Australian Design Rules (ADR), this heavy-duty side tipper delivers outstanding stability, safety, and efficiency for bulk material transport.

With a high-tensile steel chassis, reliable hydraulic tipping system, and premium brand components (FUWA, JOST, WABCO), this trailer is widely used across mining, construction, agriculture, and waste management sectors in Australia.

Built for long service life and low maintenance, it is also customizable for 40HQ and 40FR container shipping, ensuring cost-efficient international delivery.

Key Features

1. ADR-Compliant for Australian Operations

TWL 3-axle side tipper trailers are designed and manufactured in full compliance with Australian Design Rules, ensuring legal road use, high safety standards, and smooth registration across different Australian states. This compliance makes them a reliable choice for long-term fleet deployment in Australia.

2. Heavy-Duty and Durable Construction

The trailer features a high-tensile steel fabricated I-beam chassis with a strength rating of 345 MPa, providing excellent resistance to fatigue and deformation. Automatic submerged-arc welding guarantees consistent structural quality, allowing the trailer to withstand harsh mining, construction, and off-road working conditions.

3. Stable 3-Axle Load Distribution

With three high-capacity axles, the trailer offers improved load balance and driving stability when carrying heavy bulk materials. This configuration reduces stress on individual axles, enhances handling performance, and supports payloads of up to 40 tonnes during long-distance transport.

4. Efficient and Safe Side Tipping System

The dual hydraulic side tipping cylinders deliver smooth, controlled, and fast unloading, improving overall operating efficiency. This side tipper design reduces unloading time while maintaining a high level of safety during material discharge.

5. Low Maintenance and Long Service Life

Reinforced structural components combined with premium braking and running gear significantly reduce maintenance frequency and downtime. This design approach helps lower total operating costs and extends the service life of the trailer.

6. Flexible Customization Options

TWL offers a wide range of customization options, including suspension types, wheel rims, kingpin sizes, road-train brackets, and container loading solutions. Each trailer can be tailored to specific operational requirements and Australian transport conditions.

Product Specification

| Category | Item | Specification |

| General | Overall Length | 34 FT (10,500 mm) |

| Overall Width | 2,480 mm | |

| Overall Height | 2,840 mm | |

| Tare Weight | 8,500 kg | |

| Payload Capacity | Up to 40,000 kg | |

| Chassis & Body | Chassis Type | Heavy-duty fabricated I-beam, 345 MPa high-tensile steel |

| Welding Process | Automatic submerged-arc welding | |

| Finish | Sandblasted SA 2.5, 2K primer, 2-pack top coat | |

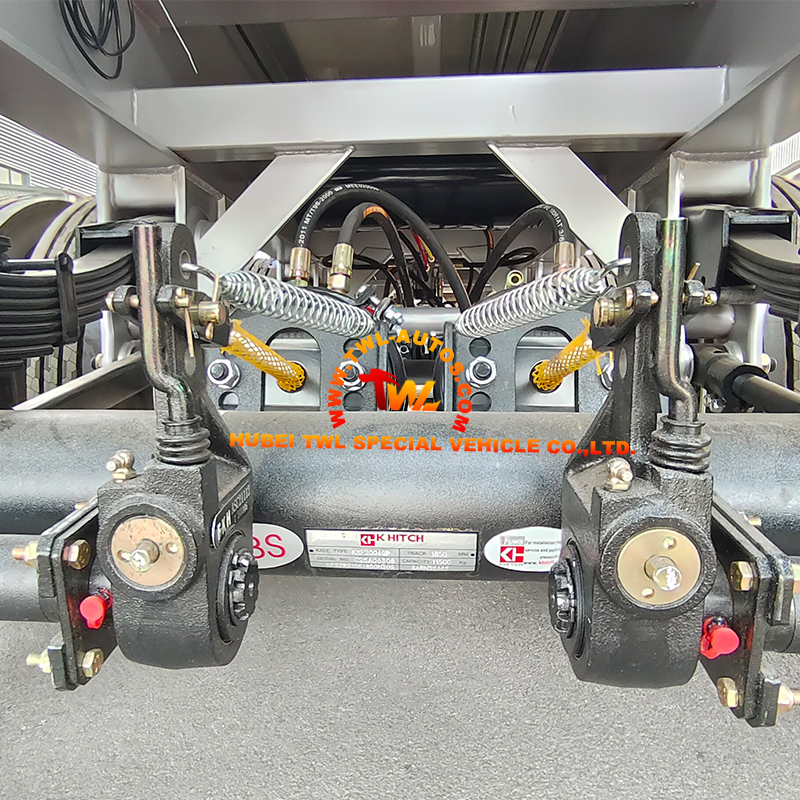

| Axles & Suspension | Axles | 3 × FUWA / K-HITCH, 11.5 tons each |

| Suspension | Mechanical, 10-leaf spring | |

| Optional Suspension | Air suspension | |

| Hydraulic System | Tipping Cylinders | Dual side tipping cylinders Ø150 mm |

| Door Cylinder | Ø80 mm | |

| Braking System | Brake Chambers | 3 × T30/30 spring brake chambers |

| Air Tanks | 40 L | |

| Brake Control | WABCO air braking system | |

| Running Gear | King Pin | JOST 50 mm or 90 mm (dual bosses) |

| Landing Gear | JOST two-speed, manual operation | |

| Wheels & Tires | Wheel Rims | 9.0R22.5, 10-stud steel rims (alloy optional) |

| PCD | 335 mm | |

| Spare Tire Rack | Dual swinging type | |

| Safety & Lighting | Mudguards | Spring-tension rubber over tri-axle group |

| Lighting | Orion ADR LED rear combination lights & side lights | |

| Wiring | ADR standard wiring with 7-pin socket | |

| Road Train | Road Train Bracket | 20 mm thick folded C-channel with reinforced gussets |

| Logistics | Container Loading | Suitable for 40HQ and 40FR container loading |

| Compliance | Certification | Australian ADR compliant |

3-Axle ADR Compliant Side Tipper Semi Trailer

- +86 199 4767 5585

- [email protected]

- Industry Park, Suizhou City,Hubei Province, China

Company Profile

Aout TWL

HUBEI TWL SPECIAL VEHICLE CO., LTD (hereinafter referred to as TWL), one of important member of CLW Group, is located in Suizhou City, Hubei Province, the capital of China’s Special Vehicles. TWL Truck has a first-class management, design, R&D, manufacturing, and sales professional team, as well as “special, new, high and sophisticated” facilities and equipment, complete manufacturing technology, and strict testing methods to ensure the production of high-quality and high-value-added products for the market. At present, we has strategic partnership with a number of well-known Chinese truck brand, including Dongfeng, Sinotruk, FAW, Foton, Shacman, ISUZU, JAC, JMC, Kama, etc. TWL Truck always adheres to the corporate philosophy of “people-oriented, customer-oriented, honesty and win-win”, and adheres to the business tenet of “development by innovation, survival by quality; integrity by service, and market by brand”.

After-Sales Service

Warranty

– The buyers can get a minimum warranty period of 12 months or 25000KM-50000KM, whichever comes first from the arrival date of shipment.

– During this period, we will send replacement parts and components to buyers by DHL, UPS, FEDEX or by air and by sea free of charge, easy-wearing spare parts are excluded.

– After warranty time, buyers can get all of spare parts of their truck at factory cost.

– This warranty does not cover any possible damage due to improper operaton, accident or misuse or damage due to any unauthorized services.

Technical Support

– The buyers can forever enioy technical support anytime and anywhere, overseas technical training before operaton is available at buyers cost or our cost.

Daily Mainteance Suggestion

– We strongly sugest you to buy some amount of basic spare pats along with your truck, the cost will be approximately 500 USD-800 USD/unit, no shipping cost.