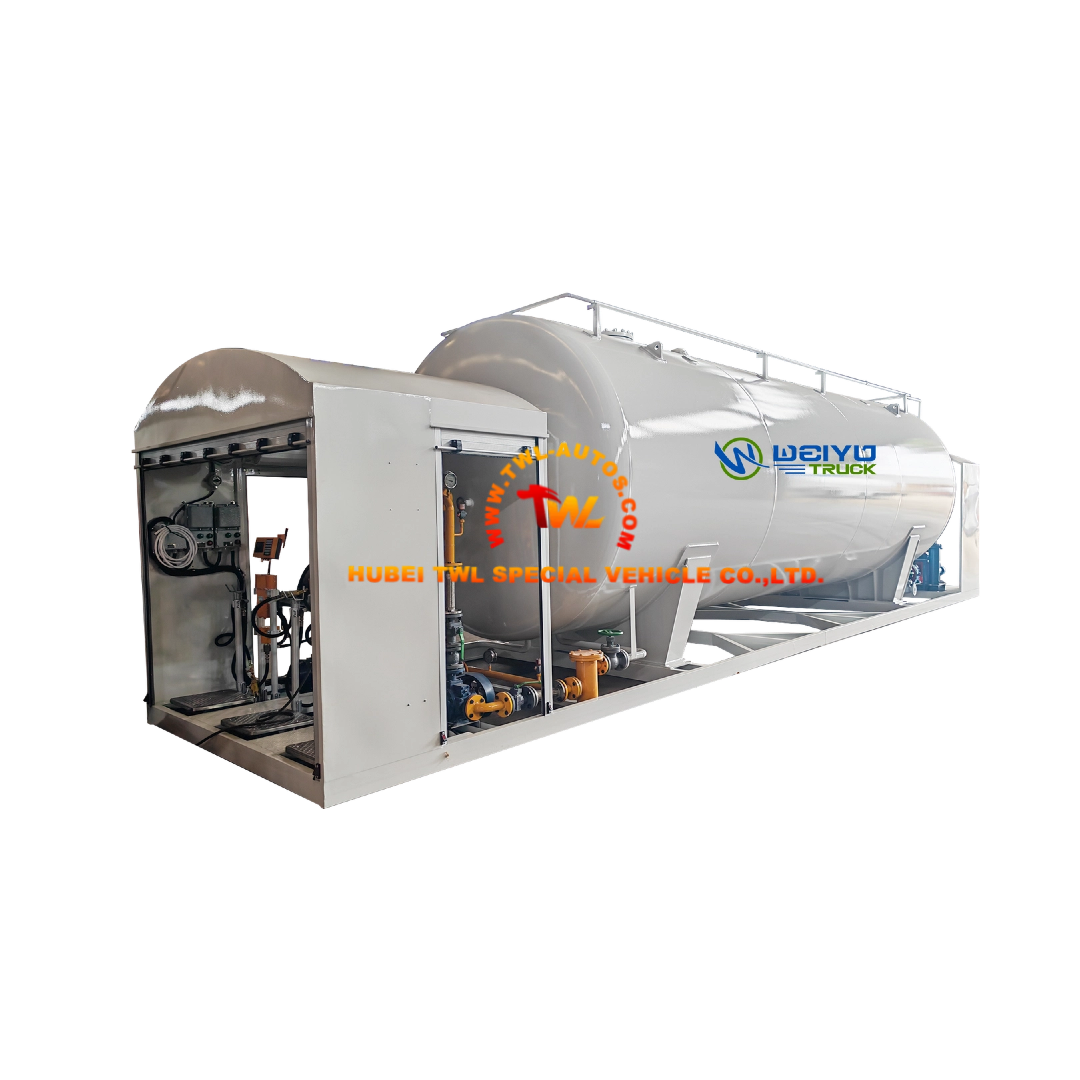

50m³ LPG Skid Mounted Filling Station

Provided by TWL, this skid-mounted LPG station delivers a reliable, ready-to-use LPG solution with high safety, efficient filling performance, and fast deployment, making it ideal for a wide range of industrial, commercial, and emergency applications.

50m³ LPG Skid Mounted Filling Station

The skid-mounted LPG station is an integrated, plug-and-play solution that combines large storage capacity, high safety standards, and efficient, smart filling operations in one compact system. Pre-assembled with piping, electrical systems, and safety devices, it significantly reduces on-site installation time and investment costs while ensuring stable and secure operation. With its flexibility, rapid deployment capability, and support for multi-cylinder filling and remote monitoring, it is an ideal LPG supply solution for urban, industrial, and temporary energy applications.

Why Choose Our LPG Skid Mounted Filling Station?

1. Certified International Compliance

Our LPG skid stations are engineered and manufactured in strict accordance with GB150 and ASME pressure vessel standards, and fully comply with China’s Pressure Vessel Safety Supervision Regulations.

All pressure vessel welds undergo 100% radiographic testing (RT) and magnetic particle inspection (MT) to ensure maximum safety and leak-free operation.

2. Turnkey LPG Skid Station with Smart Technology

We offer a complete plug-and-play LPG skid station solution, equipped with 4G smart filling scales for real-time data transmission.

Operators can remotely monitor filling volume, manage inventory, and generate operation reports, while automatic emergency shut-off and gas leakage detection systems significantly reduce safety risks.

3. Rapid Installation & Lower Total Cost

Compared with traditional on-site constructed LPG stations, our skid-mounted LPG station is pre-fabricated and factory-tested.

Installation can be completed within days on a simple concrete foundation, reducing construction time, labor costs, and site downtime.

4. Reliable Quality & Strong After-Sales Support

Backed by CLW Group’s 1-year warranty, we provide full technical support, operator training, and spare parts supply.

All stations are built using Q345R pressure vessel steel, explosion-proof motors, and high-quality valves, ensuring long-term performance even in harsh environments.

5. Flexible Customization & Capacity Options

Available capacities range from 5m³ to 200m³, with customizable pressure ratings, flow rates, and optional cold-climate solutions.

6. Proven Success in Africa

With 10+ years of experience supplying LPG skid stations across Africa, our products have earned strong market acceptance and positive customer feedback.

|  |  |

High-Capacity LPG Storage SystemEquipped with a 50m³ LPG storage tank made of high-strength Q345R carbon steel, the unit is engineered in compliance with pressure vessel standards. The tank features a 14mm shell and 16mm end dishes, ensuring reliable performance under design pressures up to 1.77 MPa and temperatures ranging from -19°C to 50°C. | Integrated Filling & Safety ConfigurationThe station comes with dual explosion-proof transfer pumps, three filling scales with 4G remote data transmission, and an LPG compressor for loading, unloading, and pressure control. A full set of safety components—including sprinklers, safety valves, gas detectors, and level gauges—ensures stable and safe operation during daily use. | Modular Plug-and-Use DesignWith a compact footprint of 12,200 × 2,728 × 3,400 mm, the skid-mounted system adopts a fully pre-wired and pre-piped design. It includes an enclosed roll-off filling room, LED lighting, and a centralized electrical control box, allowing fast on-site deployment with minimal installation work. |

Product Specification

| Specification | ||

| Overall dimension of skid station(length*width*height) | 12200*2728*3284 mm | |

| Volume of Tank | 50 CBM/50,000L | |

| Filling Weight | 25000 kg/25 Tons | |

| Tank Weight | 11500 kg | |

| Thickness of Shell (mm) | 14 mm | |

| Thickness of End plate (mm) | 16 mm | |

| Tank Diameter (mm) | 2700 mm | |

| Tank Dimensions (mm) (length x width x height) | 9182X2724X3290mm | |

| Material of Tank | Carbon Steel Q345R | |

| Filling Medium | Liquefied Petroleum Gas ( Propane) | |

| Design Pressure | 1.71 MPa | |

| Corrosion Allowance | 1 mm | |

| Medium Density | 420 kg/ cbm (50 ℃) | |

| Manufacturing Standard: Pressure vessels, Supervision Regulation on Safety Technology for Stationary Pressure Vessels of China. | ||

| Main parts of LPG Tank | ||

| Item | Specification/ mm | Quantity |

| Discharge Pipe | DN50 | 1 |

| Inflow Pipe | DN50 | 1 |

| Outlet | DN50 | 1 |

| Gas phase balance pipes | DN50 | 2 |

| Manhole | DN450 | 1 |

| Drain Hole | DN50 | 1 |

| Other tank accessories:Cut-off Valve, Needle Valve, Safety Valve, Liquid level meter, Pressure gauge, Temperature Gauge. | ||

| LPG Skid Parts List | ||

| Item | Model Number | Quantity |

| LPG Tank | 1 piece | |

| LPG compressor | 1 piece | |

| Pump | 2″ inlet & 2″ outlet | 2 Pieces |

| Explosive-proof Motor | 380V with 220V adapter | 3 Pieces |

| Cylinder filling scale with 4G data transmission | / | 3 Pieces |

| Pipes | / | 1 Set |

| DN50 Check Valve | / | 5 pc |

| DN50 Ball Valve | / | 8 pcs |

| DN15 Ball Valve | / | 2 pcs |

| Strainer | / | 1 pc |

| DN50 Non-return Valve | / | 2 pcs |

| DN50 Steel Anti-shock Pipe | / | 4 pcs |

| Pipeline Safety Valve | / | 2 pc |

| Control box | / | 1 pc |

| Gas Leakage Detector and panel | / | 1 pc |

| Explosive Proof Lamp | / | 2 pc |

| Level Gauge | Float ball type/Chinese brand | 1 Unit |

| Fire extinguisher | 1 Unit | |

50m³ LPG Skid Mounted Filling Station Gallery

- +86 199 4767 5585

- [email protected]

- Industry Park, Suizhou City,Hubei Province, China

Company Profile

Aout TWL

HUBEI TWL SPECIAL VEHICLE CO., LTD (hereinafter referred to as TWL), one of important member of CLW Group, is located in Suizhou City, Hubei Province, the capital of China’s Special Vehicles. TWL Truck has a first-class management, design, R&D, manufacturing, and sales professional team, as well as “special, new, high and sophisticated” facilities and equipment, complete manufacturing technology, and strict testing methods to ensure the production of high-quality and high-value-added products for the market. At present, we has strategic partnership with a number of well-known Chinese truck brand, including Dongfeng, Sinotruk, FAW, Foton, Shacman, ISUZU, JAC, JMC, Kama, etc. TWL Truck always adheres to the corporate philosophy of “people-oriented, customer-oriented, honesty and win-win”, and adheres to the business tenet of “development by innovation, survival by quality; integrity by service, and market by brand”.

After-Sales Service

Warranty

– The buyers can get a minimum warranty period of 12 months or 25000KM-50000KM, whichever comes first from the arrival date of shipment.

– During this period, we will send replacement parts and components to buyers by DHL, UPS, FEDEX or by air and by sea free of charge, easy-wearing spare parts are excluded.

– After warranty time, buyers can get all of spare parts of their truck at factory cost.

– This warranty does not cover any possible damage due to improper operaton, accident or misuse or damage due to any unauthorized services.

Technical Support

– The buyers can forever enioy technical support anytime and anywhere, overseas technical training before operaton is available at buyers cost or our cost.

Daily Mainteance Suggestion

– We strongly sugest you to buy some amount of basic spare pats along with your truck, the cost will be approximately 500 USD-800 USD/unit, no shipping cost.