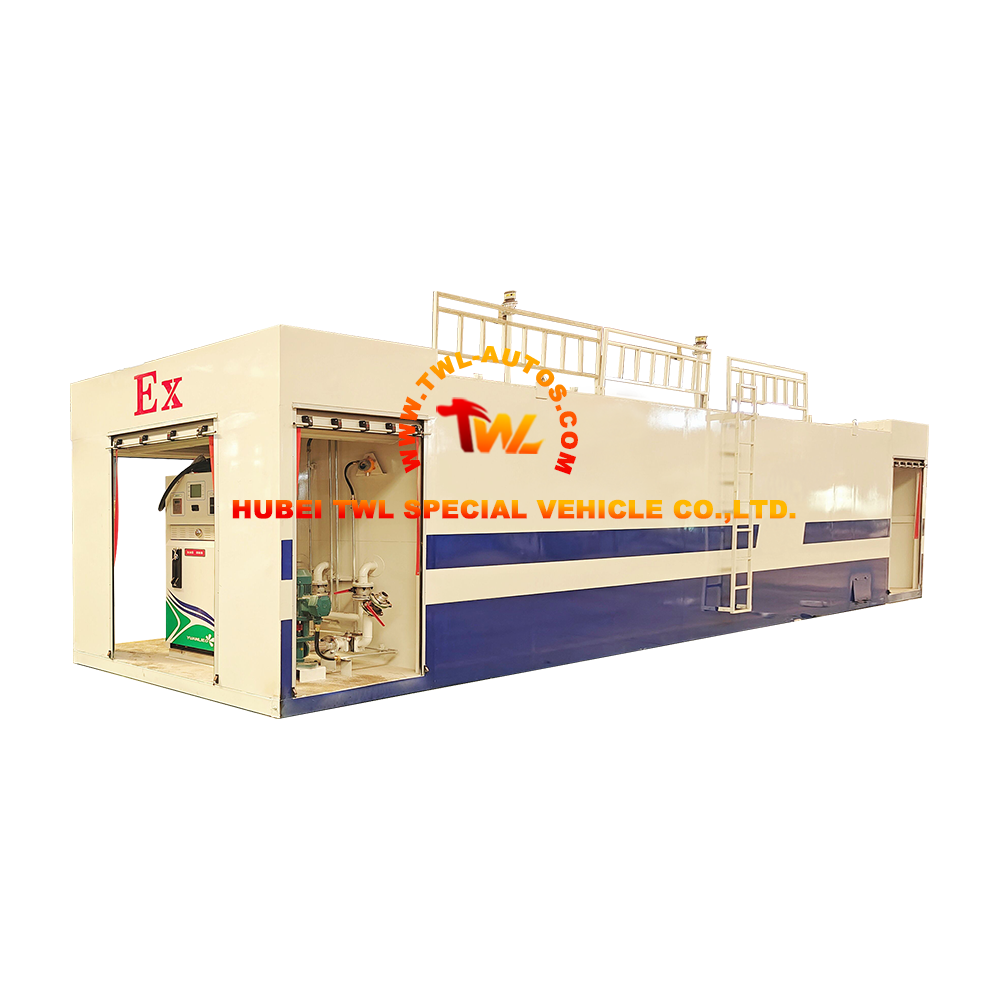

50m³ Explosion-Proof Skid-Mounted Fuel Storage Tank

TWL’s 50m³ Double-Layer Explosion-Proof Skid Fuel Station for Onsite Refueling is engineered for safe, efficient, and intelligent onsite fuel supply. Built with double-layer Q235-B carbon steel and strict explosion-proof technology, this unit ensures maximum operational safety and reliability. Designed and manufactured in TWL’s advanced production facilities, it integrates pumping, storage, metering, and automation into a fully modular fueling solution for industrial and commercial energy applications.

50m³ Explosion-Proof Skid-Mounted Fuel Storage Tank

The 50m³ Explosion-Proof Skid-Mounted Fuel Storage Tank from TWL is a high-performance modular fueling system designed for fuel storage, transfer, and onsite distribution. Constructed with a double-layer carbon steel tank (8mm inner tank / 4mm outer tank), it ensures superior mechanical strength and long-term corrosion resistance. Built in compliance with hazardous chemical containment standards, this solution delivers maximum safety in critical environments.

To ensure explosion-proof performance, the tank is equipped with a comprehensive safety system, including flame arrestors, breather valves, emergency shut-off protection, automatic fire-extinguishing units, gas detection alarms, and lightning/static grounding. These safeguards prevent leakage, ignition, and overpressure accidents in high-risk operating conditions.

The integrated refueling system features an explosion-proof unloading pump, vapor recovery system, precision flow meter dispenser, and electronic level management with real-time monitoring and alarms. Intelligent data transmission allows for remote management, IC card authorization, and optimized fuel control.

With a compact skid-mounted design and simplified installation, this solution significantly reduces construction cost and project timelines while maintaining the highest safety level. TWL provides full customization based on different fuel types, operational conditions, and regional compliance standards, making it ideal for mining, construction, transportation fleets, fuel retailing, and military or emergency energy supply applications.

Key Features

· Heavy-Duty Double-Layer Tank Design

8mm inner & 4mm outer Q235-B steel with reinforced welds for superior durability.

· Comprehensive Explosion-Proof System

Sound & light alarms, flame arrestor, pressure relief, vapor recovery, and emergency autoclose valve.

· Intelligent Fuel Level Monitoring

Magnetostrictive electronic gauge with real-time tracking and ±0.2mm precision.

· Integrated Fueling Equipment

High-efficiency explosion-proof pump and single-hose dispenser with flow rate 5–70 L/min.

· Automatic Fire Suppression

Super fine dry powder system complies with GA602-2013 standard.

· Efficient Maintenance Structure

Cleaning access port and easily replaceable filters reduce downtime.

· Modular Plug-and-Play Installation

Reduced construction work, faster deployment, and easy relocation.

· IC card & Cloud Management

Secure fuel authorization and data analytics to enhance operational control.

Product Specification

| 50m³ Equipment Parameters | |

| External Dimensions (Excluding guardrail & breather pipe) | Length: 15.11 m |

| Width: 2.65 m | |

| Height: 2.94 m | |

| Tank Structure | Inner Tank: 8mm |

| Outer Tank: 4mm | |

| Footprint | ≈ 41 m² |

| Volume | ≈ 50 m³ |

| Weight | ≈ 20 tons |

| Material | Inner/Outer Tank: Carbon Steel Q235-B |

| Working Voltage | 380V, Three-Phase, Five-Wire |

| Working Power | Max. simultaneous power consumption of all equipment ≤ 8.5 KW |

| Explosion-Proof Tank & Safety Accessories | |

| Explosion-Proof Storage Tank | Explosion-proof storage tank. Both inner and outer tanks utilize double-layer weld reinforcement technology, with weld strength higher than the butt weld strength of 12mm thick steel plate. (Atmospheric Pressure Hazardous Chemical Packaging Container) |

| Explosion-Proof Barrier Material | Explosion-proof barrier material filled in both the inner tank and the interlayer between inner/outer tanks. (Customized based on client requirements) |

| Unit Base | ST–50/2-02 |

| Explosion-Proof Electrical System | 380V Three-Phase |

| Explosion-Proof Sound & Light Alarm | Flash Frequency: 150/min; Sound Intensity ≥ 90(dB). Explosion-Proof Mark: Ex db ⅡC T4 Gb; Ex tb ⅢC T130℃ Db; Protection Level: IP65. |

| Safety Lighting System | Explosion-Proof Ceiling Light, integrated design, aesthetic and energy-saving. Explosion-Proof Mark: Ex db eb mb ⅡC T6 Gb; Ex tb ⅢC T80°C Db. |

| Oil & Gas Alarm Device | Uses imported catalytic combustion sensors and microcontroller technology. Features concentration display and sound/light alarm. Installed in refueling areas or pump/valve rooms for unloading. |

| Emergency Shut-off Device (Auto-Close Protection Valve) | Automatically seals the tank in case of uncontrollable disasters like earthquakes, tipping, falling, or impact, preventing fuel leakage. Uses internal mechanical transmission components to ensure operation even during power loss. Normally open, closes via fusible link melting in a fire. |

| Automatic Fire Extinguishing Device | Contains super fine dry powder extinguishing agent and nitrogen drive gas. Technical performance meets GA602-2013. Activation Temperature: 68-93°C. |

| Explosion-Proof Flame Arrestor & Breather Valve | Breather Valve Operating Positive Pressure: 2kPa~3kPa, Operating Negative Pressure: 1.5kPa~2kPa. Installation height >4.5m. Nominal Pressure: 1.0MPa. |

| Emergency Pressure Relief Device | Bursts open when internal pressure is excessive, rapidly depressurizing to prevent tank explosion and avoid more serious accidents. One per compartment. Opening Pressure: 27±2 KPa. |

| Overfill Prevention Device | Automatically locks the tank when the fuel level exceeds the warning height (95% of tank capacity), preventing spillage. |

| Lightning Protection & Static Grounding System | Includes static grounding alarm, lightning surge protector, aluminum alloy static clamp for connecting to tanker trucks, and copper braided grounding wire. The skid station connects to the site’s grounding electrode (user ensures ground resistance <4Ω). |

| Safety Guarding Device | With ladder and safety guardrail. |

| Tank Cleaning Access | Equipped with a cleaning access port. Reduces overall cleaning time by half compared to traditional explosion-proof skid stations while maintaining explosion-proof performance. |

| Liquid Level Measurement | |

| Electronic Level Gauge | Magnetostrictive electronic level gauge. Includes 2 probes, one touchscreen LCD display. Range: 0.15~2.7m; Error: ±0.2mm. Visualized tank medium interface with temperature monitoring. |

| Level Alarm Device | Alarm triggers at ≥90% of tank capacity. |

| Manual Measuring Device | For periodic calibration of the electronic level gauge. Can also measure tank volume if the electronic gauge fails or during power outage. |

| Refueling & Unloading | |

| Unloading Pump | Explosion-Proof Vertical Unloading Pump. Flow Rate: 30 m³/h. Explosion-Proof Motor (dⅡ), Protection Level: IP55. |

| Unloading Pump Piping System | Unloading port is standard size for connection to tanker trucks. Quick connector: DN65 self-sealing type with ball valve. Pipe Diameter: DN65. Outlet pipe end height from tank bottom: 0.15m. |

| Unloading Vapor Recovery System | Equipped with Stage I vapor recovery unit for closed-loop unloading with tanker trucks, preventing vapor release. |

| Unloading Filter | Stainless steel, 60 mesh. The filter unit is removable as a whole; the internal filter screen bracket is reusable, only the stainless steel filter mesh needs replacement. Easy maintenance, low cost. |

| Fuel Dispenser | Single Pump, Single Hose Dispenser. Self-priming pump, flow meter, LCD display, 380V motor, hose. Entire unit is explosion-proof, featuring fuse protection, hose breakaway valve, emergency stop button, static discharge function. Flow Rate: 5-70 L/min. |

| Intelligent Backend Management System | IC card refueling data statistics, real-time transmission, stable data. |

50m³ Explosion-Proof Skid-Mounted Fuel Storage Tank Gallery

- +86 199 4767 5585

- [email protected]

- Industry Park, Suizhou City,Hubei Province, China

Company Profile

Aout TWL

HUBEI TWL SPECIAL VEHICLE CO., LTD (hereinafter referred to as TWL), one of important member of CLW Group, is located in Suizhou City, Hubei Province, the capital of China’s Special Vehicles. TWL Truck has a first-class management, design, R&D, manufacturing, and sales professional team, as well as “special, new, high and sophisticated” facilities and equipment, complete manufacturing technology, and strict testing methods to ensure the production of high-quality and high-value-added products for the market. At present, we has strategic partnership with a number of well-known Chinese truck brand, including Dongfeng, Sinotruk, FAW, Foton, Shacman, ISUZU, JAC, JMC, Kama, etc. TWL Truck always adheres to the corporate philosophy of “people-oriented, customer-oriented, honesty and win-win”, and adheres to the business tenet of “development by innovation, survival by quality; integrity by service, and market by brand”.

After-Sales Service

Warranty

– The buyers can get a minimum warranty period of 12 months or 25000KM-50000KM, whichever comes first from the arrival date of shipment.

– During this period, we will send replacement parts and components to buyers by DHL, UPS, FEDEX or by air and by sea free of charge, easy-wearing spare parts are excluded.

– After warranty time, buyers can get all of spare parts of their truck at factory cost.

– This warranty does not cover any possible damage due to improper operaton, accident or misuse or damage due to any unauthorized services.

Technical Support

– The buyers can forever enioy technical support anytime and anywhere, overseas technical training before operaton is available at buyers cost or our cost.

Daily Mainteance Suggestion

– We strongly sugest you to buy some amount of basic spare pats along with your truck, the cost will be approximately 500 USD-800 USD/unit, no shipping cost.